Custom Coils

Coils for brakes, clutches, & magnets.

For more than three quarters of a century, we’ve supplied transformers, power supplies and related components of the highest quality. Today we introduce a new service, replacement coils for electrically actuated motor brakes, electromechanical clutches, and lifting magnets. With a full range of winding equipment, low cost modular tooling, and access to Foster’s extensive inventory of raw materials, we can quickly evaluate your needs, prepare an estimate and have you back in operation without delay.

Don't see what you're looking for?

We have over 20,000 transformer designs available

Typical Repair Process

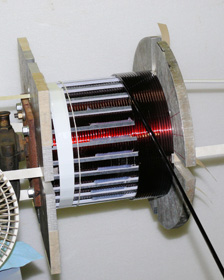

The original coil is inspected to verify the lead locations, wire gauge, number of turns, and dimensions. A wooden plug, slightly larger than the final I.D. is cut to support the coil during winding. Here a replacement coil is shown after having been removed from the machine.

The form is attached to the head stock of the winding machine and a universal backing plate attached. A single layer of insulation is wrapped around the plug before winding. NEMA MW 35C copper magnet wire rated at 200 C or copper foil is used for the winding.

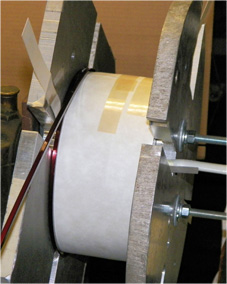

The finished coil is cuffed with Dupont Nomex™ or 3M TufQuin™ insulation before being wrapped with fiberglass tape for abrasion resistance. When the coil wire also serves as the lead out wire, fiberglass sleeving is added before wrapping the coil to protect and insulate the magnet wire. Larger coils may use copper bus bar rather than self leads.

When available, the casting or enclosure is used to test fit the coil before it is impregnated with an epoxy resin. The epoxy bonds the wire and insulation and seals out moisture. Coils may also be vacuum potted in the casting for additional protection.

A completed coil ready to ship. This coil contains over 200 pounds of copper.

This coil uses two strips of 0.040”x5” reclaimed copper.

Custom Coils and Air Core Inductors for OEM Applications